Page 108 - RedWhiteFleet_interiors_Sep10

P. 108

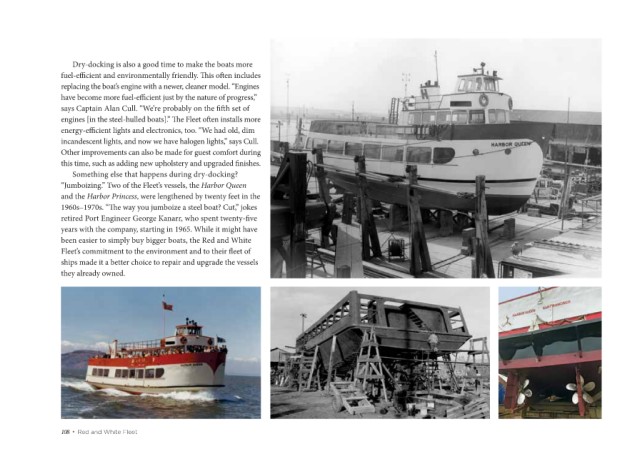

Dry-docking is also a good time to make the boats more OPPOSITE: Dry-docking occurs

fuel-efficient and environmentally friendly. This often includes every two years for thorough

replacing the boat’s engine with a newer, cleaner model. “Engines inspections, maintenance, and

have become more fuel-efficient just by the nature of progress,” occasionally more complex

improvements, such as jumboizing

says Captain Alan Cull. “We’re probably on the fifth set of and renovations. The Harbor Queen,

engines [in the steel-hulled boats].” The Fleet often installs more for example, needed to be dry-docked

energy-efficient lights and electronics, too. “We had old, dim (top) so it could be reconstructed into

incandescent lights, and now we have halogen lights,” says Cull. its jumboized form (bottom left) in

Other improvements can also be made for guest comfort during the mid-1960s.

this time, such as adding new upholstery and upgraded finishes. RIGHT: Luckily, technology of the

Something else that happens during dry-docking? last few decades has improved dry-

“Jumboizing.” Two of the Fleet’s vessels, the Harbor Queen docking procedures to be safer and

and the Harbor Princess, were lengthened by twenty feet in the more efficient. As can be seen here,

1960s–1970s. “The way you jumboize a steel boat? Cut,” jokes the Harbor Queen now slides into

retired Port Engineer George Kanarr, who spent twenty-five an all-metal frame for dry-docking,

rather than needing to be balanced

years with the company, starting in 1965. While it might have by ropes on top of wooden stands

been easier to simply buy bigger boats, the Red and White (opposite, top).

Fleet’s commitment to the environment and to their fleet of

ships made it a better choice to repair and upgrade the vessels

they already owned.

108 • Red and White Fleet Evolution • 109