Page 107 - RedWhiteFleet_interiors_Sep10

P. 107

LEFT: The Red and White Fleet

maintains a very close relationship

with the Inlandboatmen’s Union

(IBU), which provides an opportunity

for the company to hire needed short-

term employees and gives waterfront

workers a clear avenue to regular

job opportunities. Current Red and

White Fleet owner Tom Escher

can be seen here celebrating the

IBU’s centennial with IBU National

President Marina Secchitano

Escher’s grade? An A, which was an early indicator of his dry-dock to be properly prepared. “We send a blocking plan (far left).

lifelong respect for unions. to the shipyard,” says Captain Alan Cull, who has been with

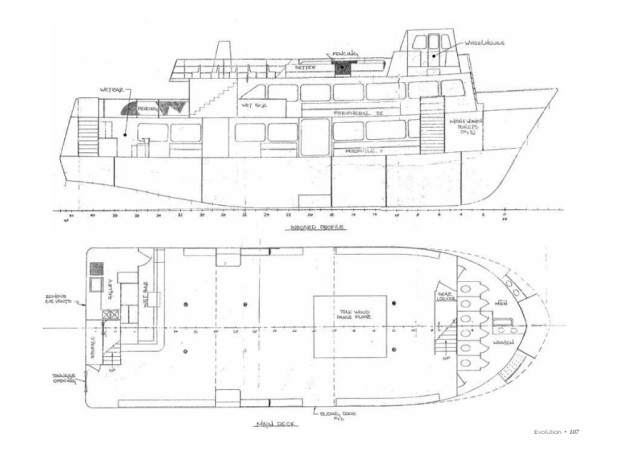

In an industry where union-employer relationships are the Fleet for over ten years. “It’s almost like a negative. We lay OPPOSITE: A schematic plan of

not always easy, Escher has distinguished himself by always out wooden blocks on a platform that will meet up perfectly one of the Red and White Fleet boats.

It takes a group of skilled engineers

seeking to cooperate. When he purchased the Red and White with the hull. Then they sail the boat over the top . . . then a and mechanics to not only build these

Fleet in 1997, he negotiated with the IBU, coming to a startup diver goes underneath and puts everything in exactly the right sightseeing vessels, but also maintain

agreement that gave the union top-to-bottom representation place.” After the boat and the blocks are lined up correctly, a them and improve them.

in the company. “Tom is a generous leader,” says Secchitano. platform rises up underneath the boat. “The boat rises up out

“He is well versed in the history of the industry and honors of the water, the water drains out, they pressure-wash, paint

its traditions—and he’s the only employer who gives his staff the bottom, and clean it all up,” explains Cull.

Harry Bridges’s birthday off!” Additional work includes attending to propellers and

rudders and measuring how much corrosion has occurred.

DRY-DOCKING The Fleet follows the model of “repair, don’t replace.” With the

Every two years, each vessel owned by the Red and White Fleet exception of the newer Enhydra, which is aluminum, all of the

must be pulled completely out of the water in order to undergo steel-hull vessels in the company (the Harbor Queen, Royal

necessary maintenance, a routine known as dry-docking. It’s a Prince, and Harbor Princess) are older than most operating

complicated process that must be planned months in advance, on the Bay. “Steel is more durable,” says Cull. Newer boats are

with plenty of communication between the Fleet’s engineers often made with aluminum hulls, which don’t hold up as well

and the shipyard that carries out the work. as the older steel-hulled boats. Cull adds, “Our boats are still

Because each vessel’s hull has a unique shape, the Fleet’s running because we’ve got a really good maintenance team . . .

engineers must send ahead instructions in order for the They’ve put a lot of money into these boats over the years.”

106 • Red and White Fleet Evolution • 107